close

Choose Your Site

Global

Social Media

| Paper Bag Width: | |

|---|---|

| Paper Bag Bottom Width: | |

| Paper Sheet Width: | |

| Paper Sheet Length: | |

| Min sheet size: | |

| Availability: | |

| Quantity: | |

AB

KXITE

This machine equips advanced compact servo handle cut-off system to replace the traditional complex mechanical structure, which reduced the setup time. The bag making machine and handle making unit have separate servo control systems to avoid the handle waste.

This machine equips advanced compact servo handle cut-off system to replace the traditional complex mechanical structure, which reduced the setup time. The bag making machine and handle making unit have separate servo control systems to avoid the handle waste.

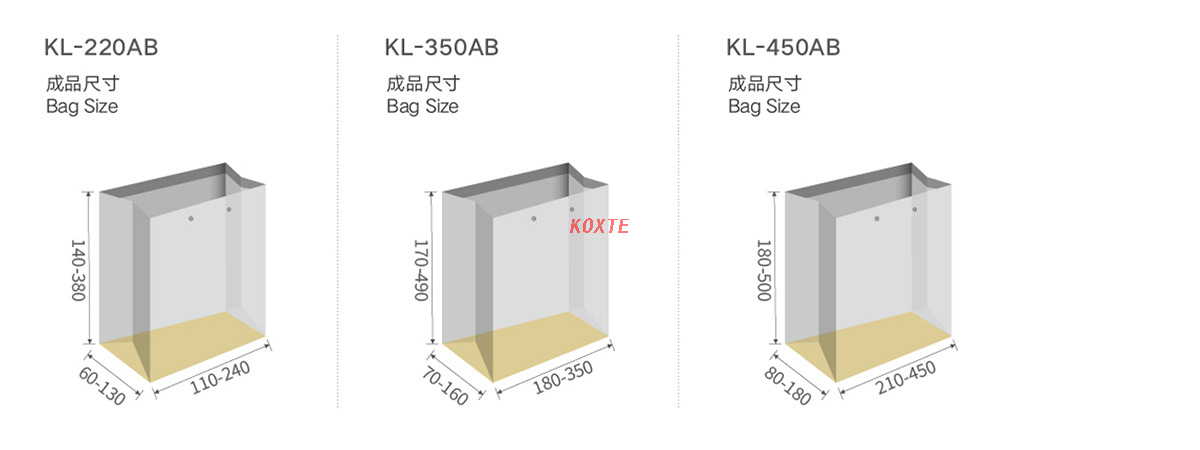

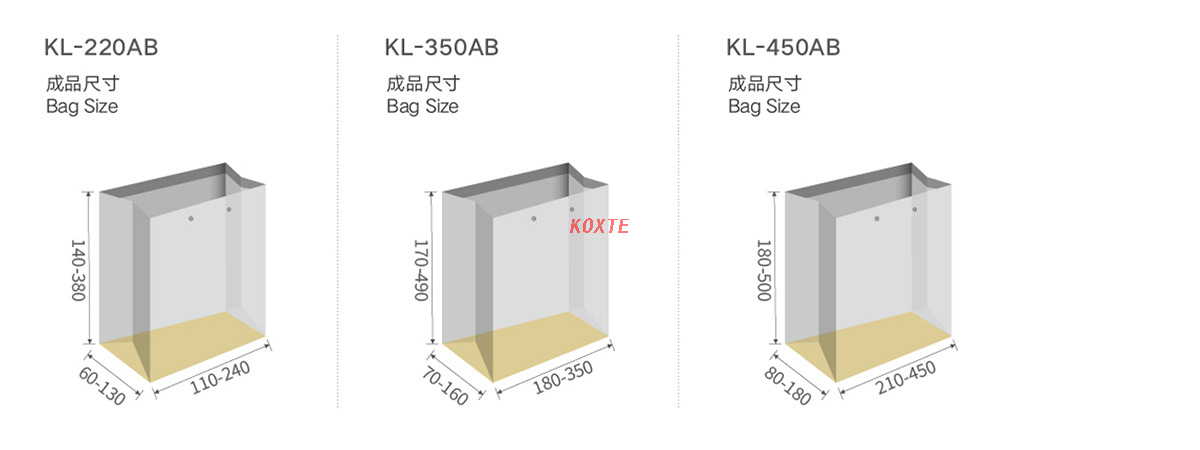

| Model | KL-220AB |

| Paper Bag Width | 110-240mm /4.33-9.44inch |

| Paper Bag Bottom Width | 60-120mm / 2.36-4.75inch |

| Paper Sheet Width | 380-700mm / 14.96-27.56inch |

| Paper Sheet Length | 240-440mm / 9.44-17.32inch |

| Paper Weight | A.Kraft Paper: 100-200g/m2 B.Art Paper+pp Laminating: 120-230g/m2 Recommend that paper thickness above 200gsm die cutting before operation |

| Max. Bottom Card L ×W | 110 × 230mm |

| Min. Bottom Card L ×W | 50× 100mm |

| Bottom reinforced card thickness | 150-450g/m2 |

| Punching Hole Distance | 60.100mm (Punching hole distance can be customized according to actual needs, the above is the standard hole distance) |

| Hole Diameter | φ4 φ5 φ6 |

| Working Speed | 50-85pcs/min |

| Glue Type | Water-based glue (additional hot-melt glue system available for side gluing) |

| Total Power | 30KW 380V 50HZ |

| Machine Weight | 14T |

| Machine Dimension | 20000×1930×1920mm |

| Note : Working speed varies depending on paper quality, paper thickness, printing effect with or without laminate PP film, glue qulty,paper size, climate and work shop environment. | |

| Model | KL-220AB |

| Paper Bag Width | 110-240mm /4.33-9.44inch |

| Paper Bag Bottom Width | 60-120mm / 2.36-4.75inch |

| Paper Sheet Width | 380-700mm / 14.96-27.56inch |

| Paper Sheet Length | 240-440mm / 9.44-17.32inch |

| Paper Weight | A.Kraft Paper: 100-200g/m2 B.Art Paper+pp Laminating: 120-230g/m2 Recommend that paper thickness above 200gsm die cutting before operation |

| Max. Bottom Card L ×W | 110 × 230mm |

| Min. Bottom Card L ×W | 50× 100mm |

| Bottom reinforced card thickness | 150-450g/m2 |

| Punching Hole Distance | 60.100mm (Punching hole distance can be customized according to actual needs, the above is the standard hole distance) |

| Hole Diameter | φ4 φ5 φ6 |

| Working Speed | 50-85pcs/min |

| Glue Type | Water-based glue (additional hot-melt glue system available for side gluing) |

| Total Power | 30KW 380V 50HZ |

| Machine Weight | 14T |

| Machine Dimension | 20000×1930×1920mm |

| Note : Working speed varies depending on paper quality, paper thickness, printing effect with or without laminate PP film, glue qulty,paper size, climate and work shop environment. | |

Home | Video | About Us | Contact Us

| | Address: No. 8 Jinfei Road Henghe Industrial Zone Feiyun Street, Ruian, Wenzhou |

| | Custom Support & Sale: +86-136 2587 3008 |

| | Working Time: 08:00–23:00 |

| |