close

Choose Your Site

Global

Social Media

| Speed of Making Bag: | |

|---|---|

| Machine Speed: | |

| Unwinding Part: | |

| Availability: | |

| Quantity: | |

KXT-HB800

kxite

Introduction of DHL paper padded mailer bag making machine

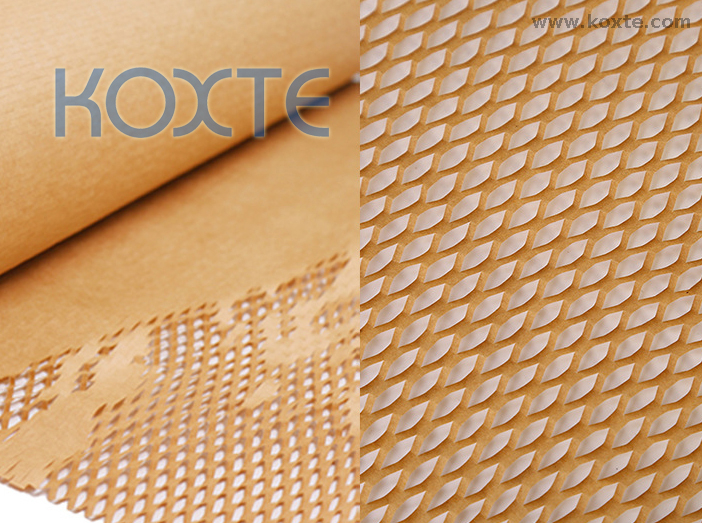

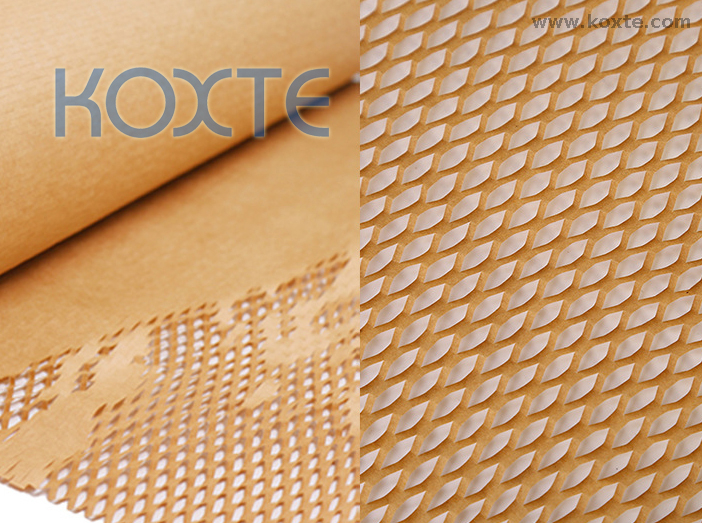

Honeycomb paper cushion mailer bag making machine is designed to produce the honeycomb or paper bubble or corrugated padded bag mailer envelope bags to be widely used in protective packaigng industry like DHL, UPS, Fedex express industry and also used in Amazon express delivery and a lot E-commerce industry to protect goods during the trasportation.

Description of DHL paper padded mailer bag making machine

Paper bags produced by Honeycomb Paper Envelope Machine and Paper Bubble Envelope Machine can replace our common plastic bubble film packaging bags, to reduce the white plastics pollution to make our earth greener, cleaner and more livable for human being.

The machine can be optional for other bags below:

1. Bottom Gusset Bag Machine: Bottom envelope bag can replace gray and black film express bag, paper-plastic composite bag, and transparent paper can replace POPP clothing bag, hospital pill bag and so on.

2. Honeycomb Paper Rolling Cutting Machine: Honeycomb paper can replace bubble film to package cosmetics, medicine bottles, circuit boards, electronic originals, etc., with a good buffer effect.

3. Corrugated Paper Envelope Machine: Corrugated cardboard paper to replace the honeycomb paper as the protection cushion.

Introduction of DHL paper padded mailer bag making machine

Honeycomb paper cushion mailer bag making machine is designed to produce the honeycomb or paper bubble or corrugated padded bag mailer envelope bags to be widely used in protective packaigng industry like DHL, UPS, Fedex express industry and also used in Amazon express delivery and a lot E-commerce industry to protect goods during the trasportation.

Description of DHL paper padded mailer bag making machine

Paper bags produced by Honeycomb Paper Envelope Machine and Paper Bubble Envelope Machine can replace our common plastic bubble film packaging bags, to reduce the white plastics pollution to make our earth greener, cleaner and more livable for human being.

The machine can be optional for other bags below:

1. Bottom Gusset Bag Machine: Bottom envelope bag can replace gray and black film express bag, paper-plastic composite bag, and transparent paper can replace POPP clothing bag, hospital pill bag and so on.

2. Honeycomb Paper Rolling Cutting Machine: Honeycomb paper can replace bubble film to package cosmetics, medicine bottles, circuit boards, electronic originals, etc., with a good buffer effect.

3. Corrugated Paper Envelope Machine: Corrugated cardboard paper to replace the honeycomb paper as the protection cushion.

Material: | Kraft Paper ,Honeycomb Paper | |||

Unwinding Width | ≦1200 mm | Unwinding Diameter | ≦1200 mm | |

Speed of Making Bag | 30-50 units /min | |||

Machine Speed | 60 /min | |||

Bag Width | ≦800 mm | Bag Length | 650 mm | |

Unwinding Part | Shaftless pneumatic Cone Jacking Device | |||

Voltage of Power Supply | 22V-380V,50HZ | |||

Total Power | 28 KW | |||

Machine Weight | 15.6 T | |||

Appearance Color of Machine | White Plus Gray&Yellow | |||

Machine Dimension | 31000mm*2200mm*2250mm | |||

14 mm thick Steel Slates for The Whole Machine (The machine is plastic sprayed.) | ||||

Air Supply | Auxiliary Device | |||

Summary of Hexcel wrap padded mailer making machine

1. Hexcelwrap padded mailer bag making machine is specially designed for producing high quality mailer bags. By combining kraft paper with in-line bubble paper, honeycomb paper or corrugated paper, the machine provides a durable and reliable packaging solution.

2. The bag making process is to send three rolls of kraft paper into the release frame, and the middle layer is designated to press air bubbles or other paper materials. The paper layers are reinforced by spraying glue at fixed points, and then pressed vertically and horizontally. Additional horizontal spraying and folding before heat pressing and cutting to create eco-friendly cushion bags for express delivery.

3. Using advanced motion control technology, this intelligent machine can seamlessly manage the unwinding, cutting and forming of materials to produce flat and environmentally friendly paper bags. The seals created are strong and reliable, while the operating procedures are simple and easy to use. In short, this quality machine is the ideal solution for special bag making requirements.

4. This machine is multi-purpose, and can produce various mail bags such as honeycomb mail bags, corrugated paper mail bags, embossed paper air bubble mail bags, etc.

Material: | Kraft Paper ,Honeycomb Paper | |||

Unwinding Width | ≦1200 mm | Unwinding Diameter | ≦1200 mm | |

Speed of Making Bag | 30-50 units /min | |||

Machine Speed | 60 /min | |||

Bag Width | ≦800 mm | Bag Length | 650 mm | |

Unwinding Part | Shaftless pneumatic Cone Jacking Device | |||

Voltage of Power Supply | 22V-380V,50HZ | |||

Total Power | 28 KW | |||

Machine Weight | 15.6 T | |||

Appearance Color of Machine | White Plus Gray&Yellow | |||

Machine Dimension | 31000mm*2200mm*2250mm | |||

14 mm thick Steel Slates for The Whole Machine (The machine is plastic sprayed.) | ||||

Air Supply | Auxiliary Device | |||

Summary of Hexcel wrap padded mailer making machine

1. Hexcelwrap padded mailer bag making machine is specially designed for producing high quality mailer bags. By combining kraft paper with in-line bubble paper, honeycomb paper or corrugated paper, the machine provides a durable and reliable packaging solution.

2. The bag making process is to send three rolls of kraft paper into the release frame, and the middle layer is designated to press air bubbles or other paper materials. The paper layers are reinforced by spraying glue at fixed points, and then pressed vertically and horizontally. Additional horizontal spraying and folding before heat pressing and cutting to create eco-friendly cushion bags for express delivery.

3. Using advanced motion control technology, this intelligent machine can seamlessly manage the unwinding, cutting and forming of materials to produce flat and environmentally friendly paper bags. The seals created are strong and reliable, while the operating procedures are simple and easy to use. In short, this quality machine is the ideal solution for special bag making requirements.

4. This machine is multi-purpose, and can produce various mail bags such as honeycomb mail bags, corrugated paper mail bags, embossed paper air bubble mail bags, etc.

Home | Video | About Us | Contact Us

| | Address: No. 8 Jinfei Road Henghe Industrial Zone Feiyun Street, Ruian, Wenzhou |

| | Custom Support & Sale: +86-136 2587 3008 |

| | Working Time: 08:00–23:00 |

| |